QA

QA QA

QA

QA

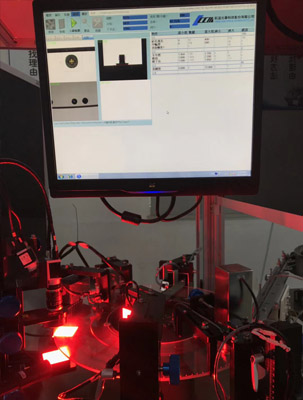

Stable and high-quality product quality requires refined production management and professional technical processes. SULATER's independent laboratory equipment was responsible for all aspects of the manufacturing process and all aspects of the finished product. All products are only passed through rigorous and serious testing. Data analysis and assembly verification using the site will ensure 100% product qualification and stability.

Rigorous + professional was the basic requirement of our team. It is probably easy to ensure the quality of a screw, but it is not easy to make millions of stable screws. It is subject to the precision and stability of raw materials and machinery, molds, The impact of many aspects such as operational experience, management level and final inspection; Sulater absolutely ensures the quality of all off-line products.

Provide quality assurance and after-sales service for all customers within one year!

HRC&HRB core hardness inspection .

HV case and core hardness inspection .

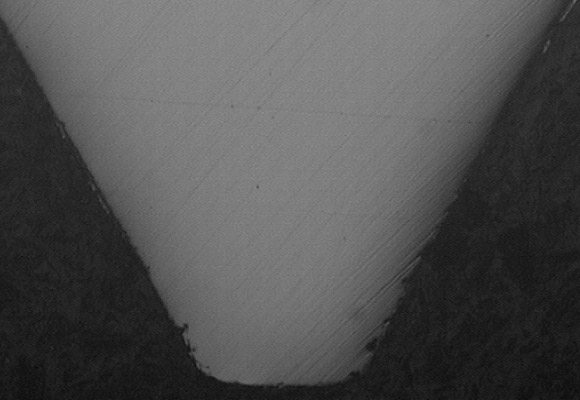

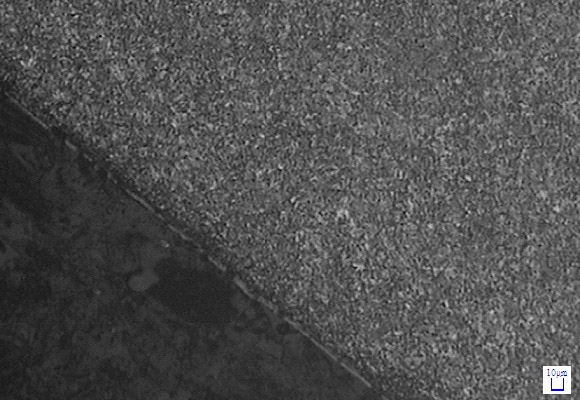

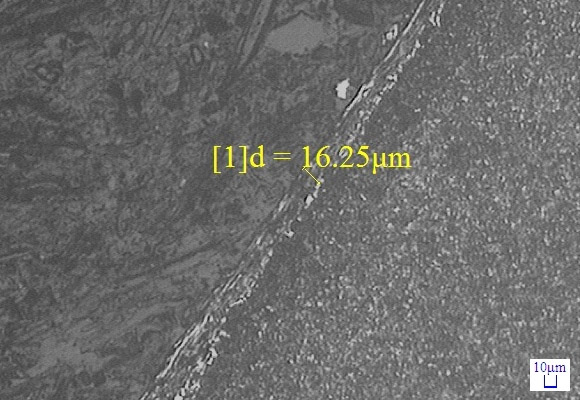

Metallographic structure

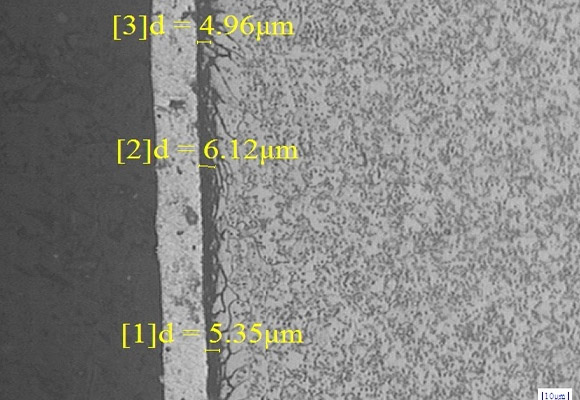

Carburization thickness

Decarburized

Non-metallic inclusion

Coating thickness

Fold thread

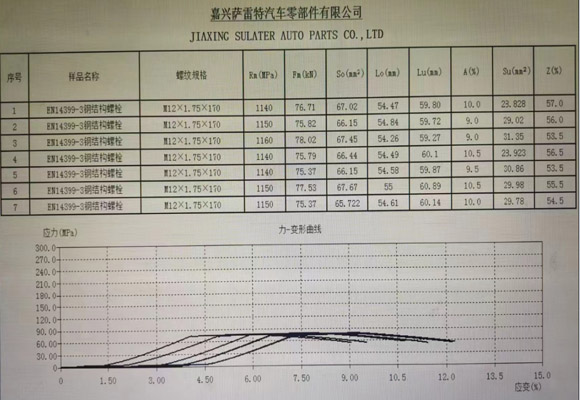

Fracture prevention

Tensile strength

Yield strength

Elongation

Reduction of area

Dimensions

Radius

Thread . reduction point angle etc.